Services

Sourcing

Strategic sourcing is the process of developing channels of supply at the lowest total cost, not just the lowest purchase price. It expands upon traditional organisational purchasing activities to embrace all activities within the procurement cycle, from specification to receipt, payment for goods and services to sourcing production lines where the labor market would increase firms’ ROI.Strategic sourcing processes aim for continuous improvement and re-evaluation of the purchasing activities of an organisation.

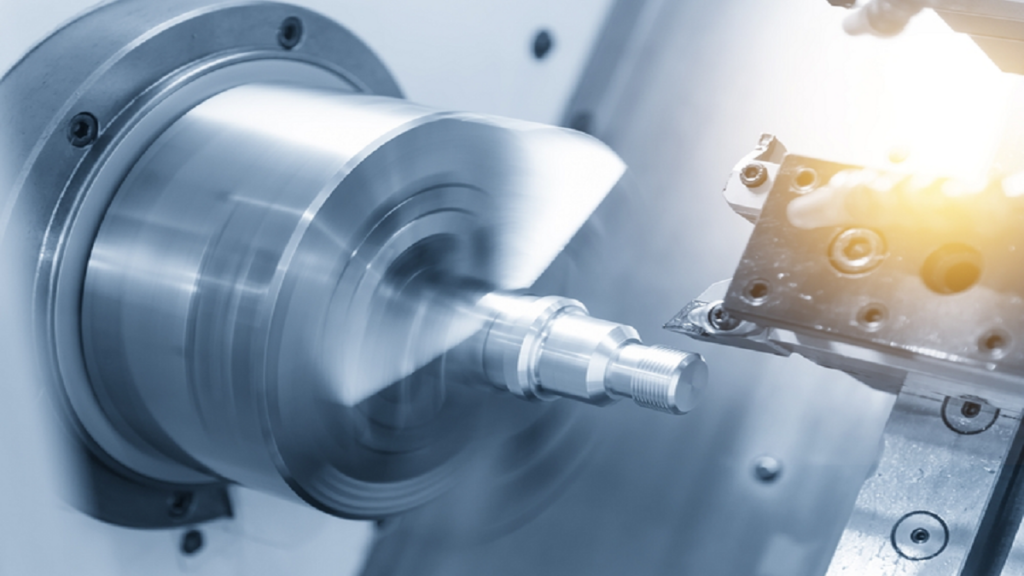

Machining

Machining is a process in which a material is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, in contrast to additive manufacturing, which uses controlled addition of material.

Plastic and rubber Moulding

Rubber molding is a molding process that produces a usable rubber product. Rubber products are made from uncured rubber or elastomers. Rubber molding creates molded rubber parts by pressing a block of rubber into a rubber molding metal cavity. The rubber is then exposed to heat, activating a chemical reaction.

Fabrication

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials.

Casting

Casting is a manufacturing process by which a molten material such as metal or plastic is introduced into a mold, allowed to solidify within the mold, and then ejected or broken out to make a fabricated part

Stamping

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Cold forgings ( Aluminum, MS and SS)

Cold forging deforms metal while it is below its recrystallization point. Cold forging increases tensile strength some and yield strength substantially while reducing ductility. Cold forging usually takes place near room temperature. The most common metals in cold forging applications are usually standard or carbon alloy steels. Cold forging is typically a closed-die process.

Screw Machining

Screw machining is the process of rapidly spinning lathes that shave metal down to the desired size. There are 2 major types of screw machines: Turret and Swiss. At the same time, both processes are able to perform more precise work as a byproduct of their tight configuration and tooling.

Assembly line

An assembly line is a manufacturing process (often called a progressive assembly) in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced. By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to work station, a finished product can be assembled faster and with less labor than by having workers carry parts to a stationary piece for assembly.

Useful Link

-

Grovel Indiabtc Connectivity

GAT NO. 73, SONAWANE WASTI, JYOTIBANAGAR, TALWADE, HAVELI,PUNE,PIMPRI-CHINCHWAD-411062,MAHARASHTRA.(INDIA)

- +91- 9665342704, 9423248766, 7972240445

- grovelindibtc@rediffmail.com, Indiabtc@rediffmail.com, info@grovelindiabtcconnectivity.com, grovelconnectivity@gmail.com, grovelqc@gmail.com

2021 © Copyrights grovelindiabtcconnectivity | Designed & Developed By Zauca